CCTV News: During this May Day holiday, many engineering builders stick to their posts and make every effort to promote the accelerated construction of major projects.

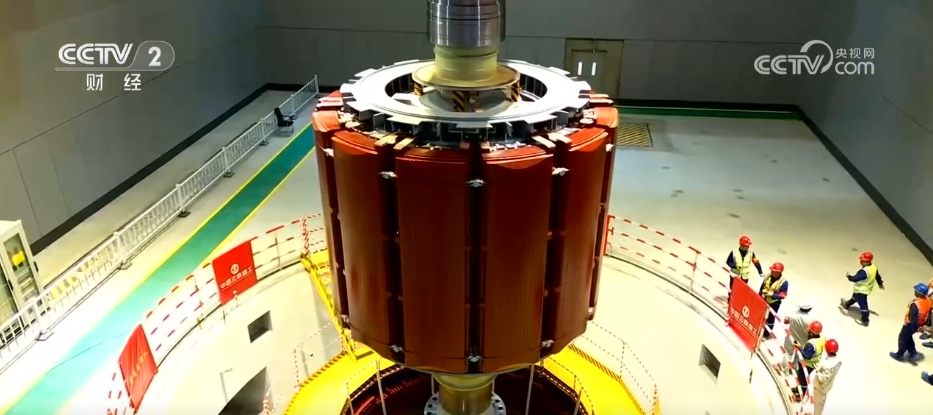

Unit 1 of Zhejiang Tiantai Pumped Storage Power Station, a key project of the national "14th Five-Year Plan", completed the rotor hoisting operation on the morning of May 2, marking the unit entering the final assembly stage and laying the foundation for the first unit to be put into production and generate power by the end of this year.

The reporter came to the power plant of the Tiantai pumped storage power station. Everyone sees that this moving red cylindrical behemoth is the generator rotor, which has been hoisted directly above the designated position by the bridge crane and is falling steadily. The rotor is nearly 5 meters in diameter and weighs 481 tons. The staff told reporters that in this process, safety, stability and precision should be paid attention to. The bridge operators and ground commanders need to cooperate closely. During the process of falling of the rotor, the unilateral gap with the stator is only about 5 cm. After the successful lifting, it marks that the unit has entered the final assembly stage, and the first machine is about to be put into production and power generation. As the pumped storage unit with the largest single-unit capacity in China, the single-unit capacity of the Tiantai Power Station reaches 425 megawatts. When the four units operate at full capacity, the hourly power generation can reach 1.7 million kWh, which is enough to meet the instantaneous electricity demand of a medium-sized city.

The reporter also learned that an important indicator of the Zhejiang Tiantai Pumped Storage Power Station has set a world record. Its rated head has reached 724 meters, which can be simply understood as the vertical drop between the upper and lower reservoirs. With such a high drop, the pipeline needs to withstand repeated impacts from high-pressure water flow. Before this, the Baihetan Hydropower Station, the world's second largest hydropower station, used 800 MPa high-strength steel for the first time. This time, R&D personnel and upstream and downstream supply chain companies jointly researched the key points, setting a new record again, developing domestic 1,000 MPa hydropower high-strength steel, and applied it on a large scale to the pipelines of the Tiantai Power Station. This is the first time in China.

Henan: Work will not stop during the holidays, and the construction of the China-Europe Express (Zhengzhou) assembly center is accelerating.

In the first four months of this year, the China-Europe Express (Zhengzhou) has launched a total of 538 trains and sent 54,494 standard containers, an increase of 60.1% and 54.0% year-on-year respectively. In order to meet the rising freight demand, the construction of the China-Europe Express (Zhengzhou) assembly center project has been accelerated. During the May Day holiday, more than 1,500 builders stick to the front line of construction to ensure that the first phase of the project is completed and put into use by the end of June.

At the construction site of the China-Europe Express (Zhengzhou) assembly center project in Henan Airport Comprehensive Economic Pilot Zone, workers are carrying out the installation of the warehouse facade exterior wall panels and the closing of the door opening. In order to ensure the progress of the project, a three-shift working system is adopted, and each shift is constructed for eight hours uninterrupted.

As the business volume continues to rise, in order to improve the existing warehousing space and meet the needs of train operation, the China-Europe Express (Zhengzhou) assembly center began to build. At present, the storage area of the first phase of the project under construction reaches 380,000 square meters, an increase of 112% from the original storage scale.