CCTV News: On February 23, the fourth-generation marine engineering installation ships independently developed by my country, the "Zhigao" and "Zhiyuan" were successfully completed in Nantong, Jiangsu. The main task of these two ships is to transport the fan, which we often call "big windmills", to the deep sea and carry out construction work such as installation. The completion of the manufacturing of these two fourth-generation marine engineering installation ships is of great significance to promoting the large-scale development of deep-sea wind power and accelerating the green and low-carbon transformation of energy.

The "Popeye" and "Deep Sea Giant" installed on offshore fans

As the fourth generation of marine engineering installation ships in my country, the two ships, the "Zhigao" and "Zhiyuan" have outstanding operating capabilities in deep sea hoisting, pile driving, etc. What are their unique designs and advanced technologies? Next, let us follow the reporter of the Central Station to get on the ship to get a close look at these two powerful offshore wind power installation tools.

These two ships are the best partners in the installation of marine equipment, and their abilities have their own strengths.

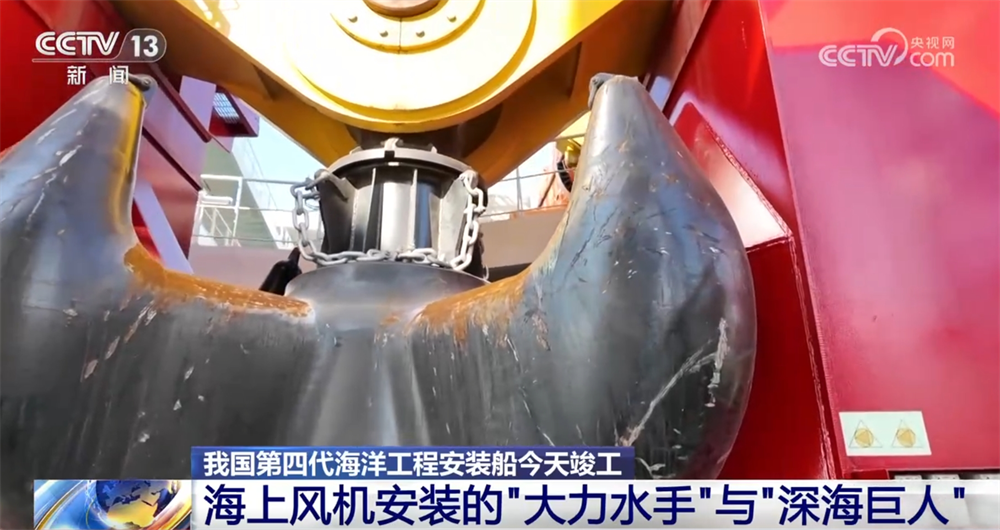

The main functions of "Zhigao" are lifting and foundation pile driving. It is like a Popeye with an extremely strong arm. The giant barrel pile located at the stern of the boat, plus the 130-meter-long arm on the top, is its main hanging system. Let's look at the huge anchor here. It is its main hook. It is like a human gripping tool. It can lift 3,600 tons of goods, which is equivalent to being able to lift 2,500 family cars at one time. It can rotate 360 degrees, which is twice the speed of rotation compared to the previous generation of offshore installation ships. Moreover, its accuracy is very high, and the accuracy error of lifting thousands of tons of cargo does not exceed 10 cm.

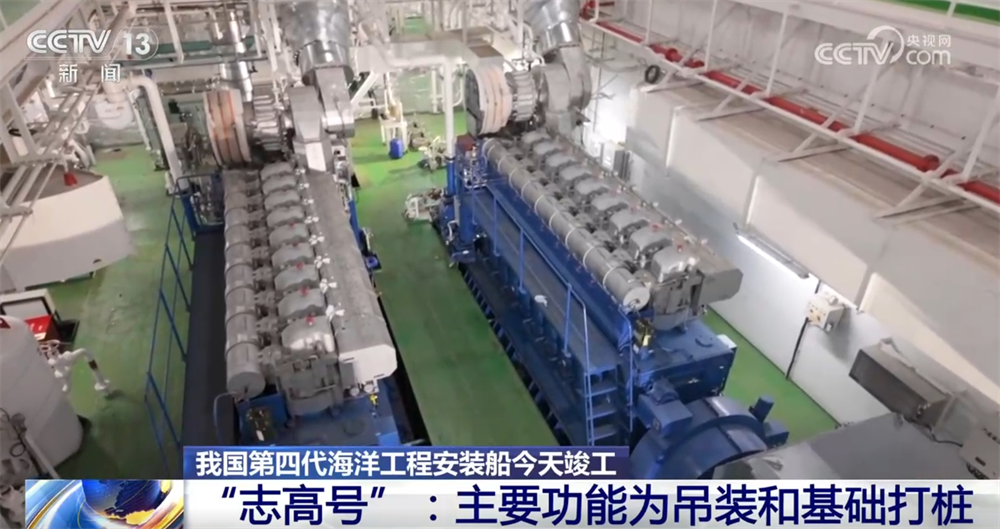

This is the main cabin of the "Zhigao". It has 4 powerful hearts, which is its generator set. It can generate 17,000 degrees of electricity in one hour, which can meet the daily electricity needs of nearly 2,000 households. With it, it can meet the entire ship's high-intensity operations all-weather.

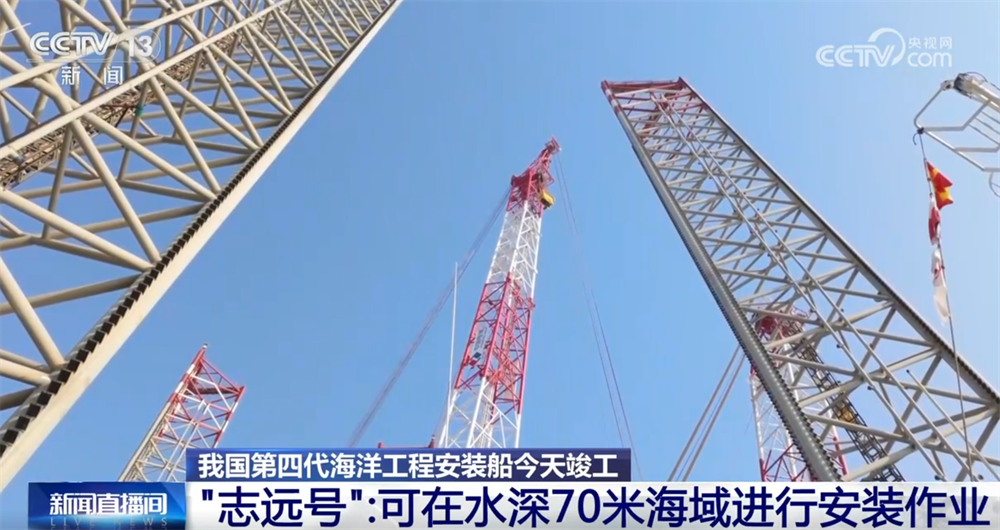

The reporter is now on the "Zhiyuan". The biggest difference between it and the "Zhigao" that floats on the sea is that the ship has 4 "long legs" of 125 meters, which is this gray frame. This allows it to penetrate deep into the seabed at the bottom of the sea and to carry out the installation of offshore wind turbines in a water depth of 70 meters. This columnar red tower is the crane of the Zhiyuan, which can lift goods to a height of 170 meters, which is equivalent to 58 floors. It is the final installation of offshore units, especially the installation of cabins and blades.

So, how did the "Zhigao" and "Zhiyuan" jointly complete the installation of a fan?

Firstly, "Zhigao" relies on the "big iron arm" to lift the steel pipe piles into the water, lift the pile hammer, and drive the steel pipe piles into the seabed, completing the foundation pile driving. Subsequently, the "Zhiyuan" used its "long legs" to steadily penetrate into the seabed and raised its hull to provide a stable platform for offshore installation. It hoistes the tower onto the foundation, and then installs the fan nacelle and fan blades one by one to the top of the tower, so that the fan is safe. The two ships are closely cooperating to meet the high-efficiency construction needs of deep-sea integrated offshore wind power with a single-unit capacity of 25 megawatts.

my country's marine engineering equipment manufacturing has ranked first in the world for seven consecutive years

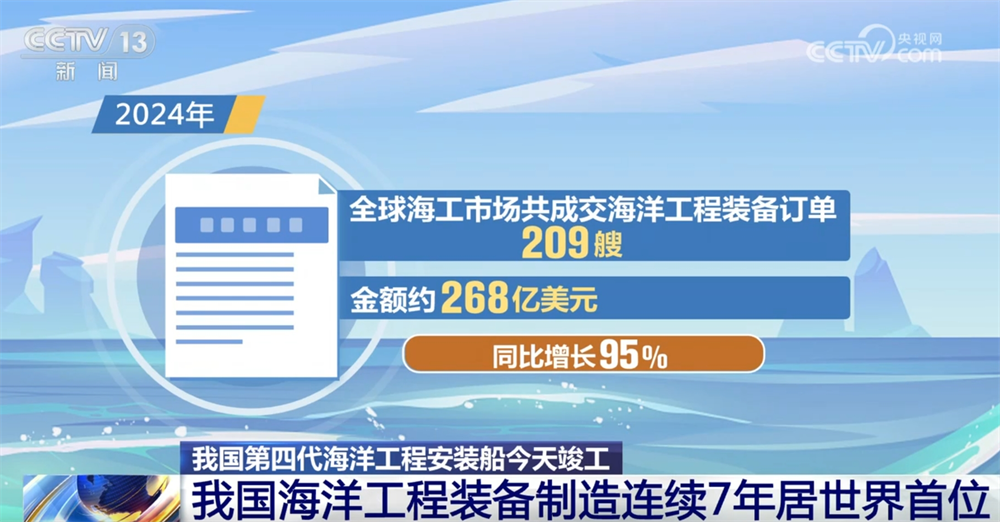

New equipment has been put into production, further consolidating my country's leading advantage in the field of marine engineering equipment, and its market share has ranked first in the world for seven consecutive years.

The Zhenhua Heavy Way, Jiangsu Nantong, which manufactures these two offshore wind power installation ships, is the location of the national offshore engineering equipment and high-tech ship advanced manufacturing cluster. The offshore engineering equipment here accounts for about 1/4 of the domestic market, and the scale of the ship manufacturing industry ranks first in the country.

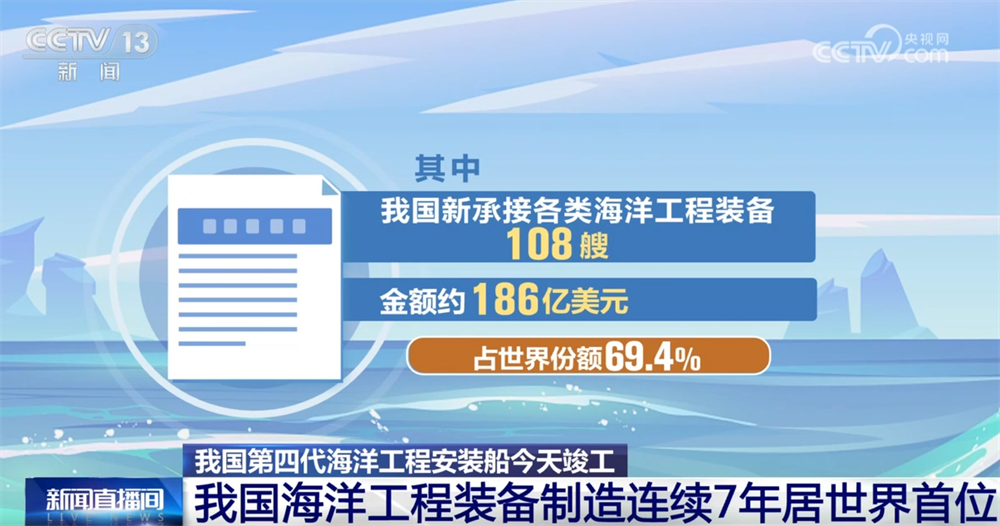

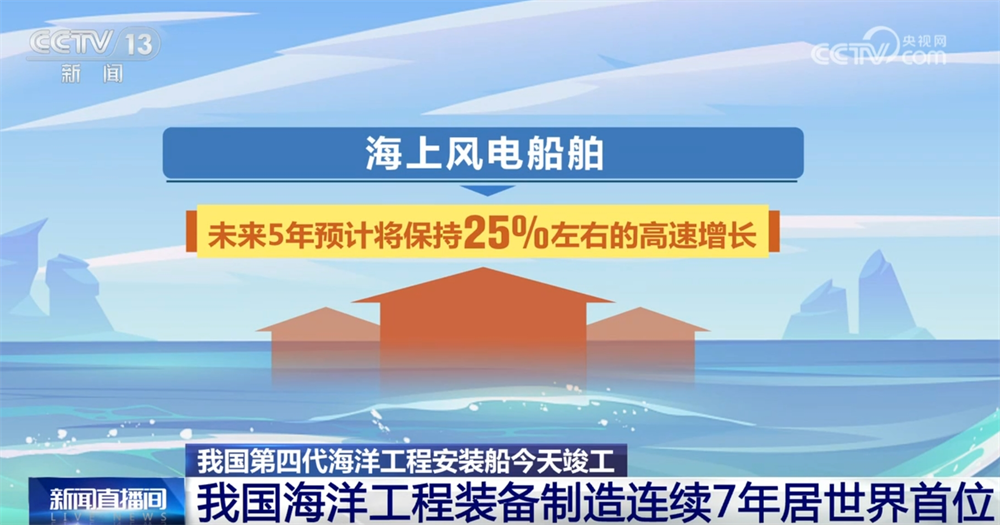

Not only in Nantong, data statistics show that in 2024, the global marine engineering market sold a total of 209 marine engineering equipment orders, with a total of approximately US$26.8 billion, a year-on-year increase of 95%. Among them, my country has undertaken 108 new marine engineering equipment ships of various types, with a total of approximately US$18.6 billion, accounting for 69.4% of the world's share. Offshore wind power ships are expected to maintain a rapid growth of around 25% in the next five years.

At the same time, my country's high-end marine marine equipment field "new content" and "green content" have continuously achieved technological breakthroughs. Orders for floating liquefied natural gas production, storage and unloading devices, floating production, storage and unloading devices, large offshore wind power installation ships, and new offshore wind power operation and maintenance ships are continuously undertaken.

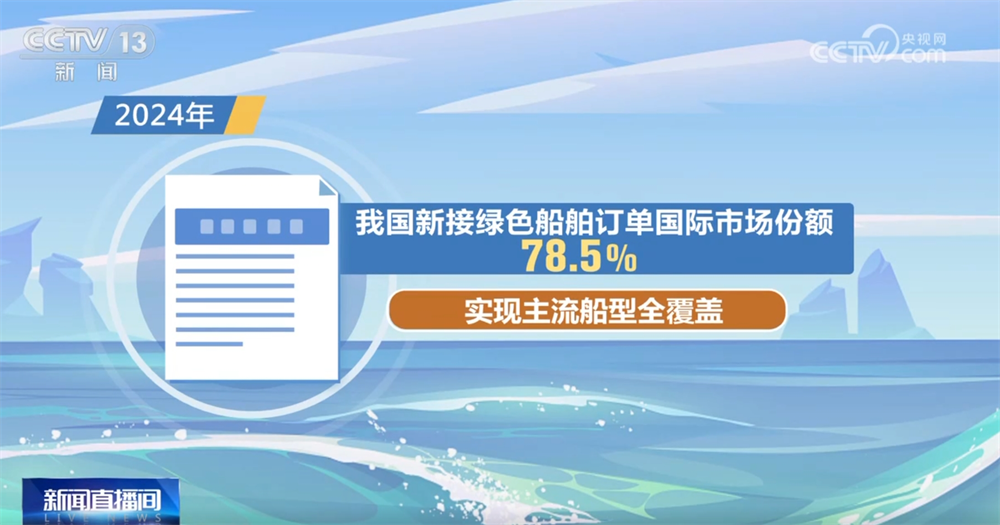

In 2024, my country's international market share of newly received green ship orders reached 78.5%, and achieved full coverage of mainstream ship types.