CCTV News: Changle District, Fuzhou, Fujian is a major textile center in my country. Faced with the wave of development of the times, the local area actively promoted the transformation and upgrading of traditional industries. As soon as construction started after the holiday, many textile companies accelerated the launch of green fiber products.

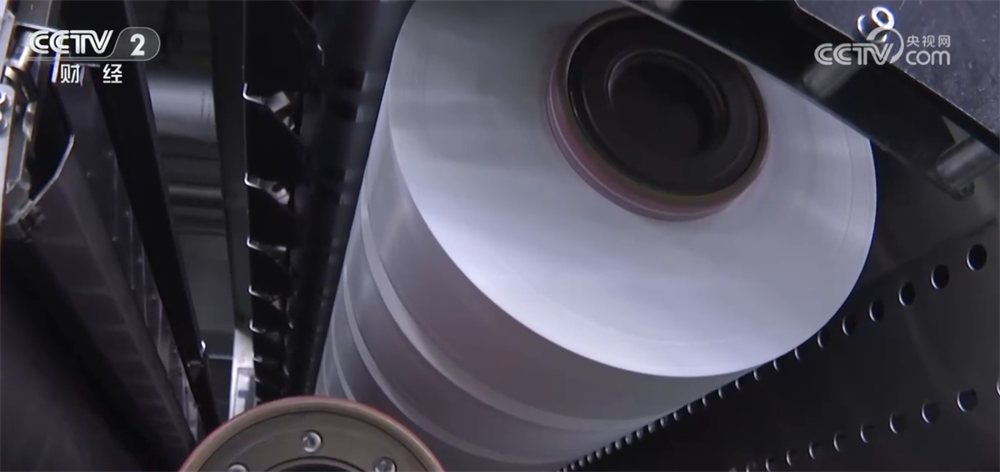

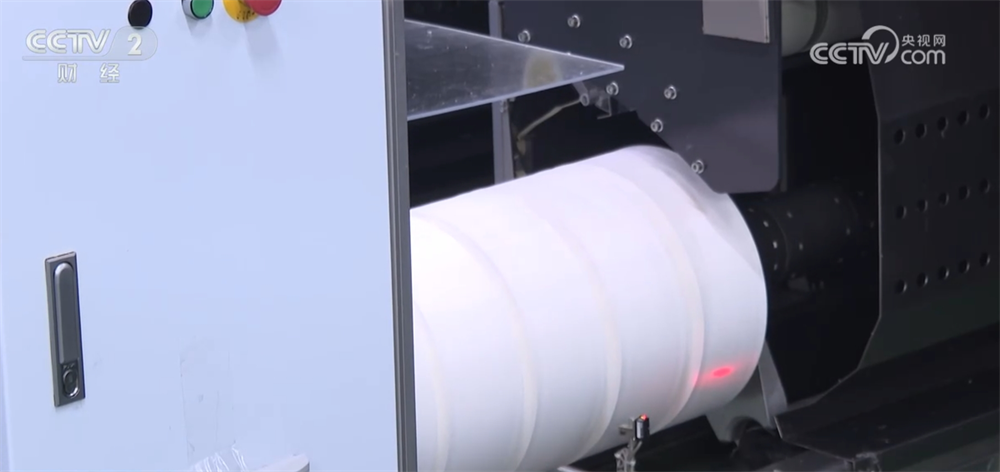

Walking into a production workshop of a leading chemical fiber yarn production company in Changle, Fuzhou, the reporter saw that a brand new nylon yarn production line was being produced at full speed. The production line does not use oil extract raw materials, but disinfects and crushes old clothes, old socks, and then goes through more than ten steps such as decolorization, melting, and brushing, and finally makes white spindles.

Li Ming, technical director of a chemical fiber production enterprise in Fujian, said: "We have achieved technical recycling and regeneration of waste clothing fabrics with a proportion of nylon content on the market through the supercritical technical route of independent intellectual property rights."

The person in charge of the enterprise's technical department introduced that at present, the production line has passed the recycling and regeneration standard certification of the international textile trading industry. It is officially put into mass production after the Spring Festival holiday this year. It is expected that the annual output can exceed 1,000 tons, which will drive thousands of downstream weaving companies and promote the listing of more green fiber products.

Li Ming said: "At present, there are more than a dozen brands that are willing to cooperate with us to develop post-consumption recycled nylon, basically distributed in Germany, Italy, France, Japan and South Korea."

In the company's sample display area, the reporter also saw that this recycled nylon yarn has been used for the production of more than 20 products such as outdoor sports products, windbreakers, and underwear. In the near future, the company also plans to further increase production lines and increase production capacity.

Fuzhou, Fujian: Exploring the path of green development, new textile materials continue to emerge

In addition to the new progress of recycled fiber products, the reporter found that some textile companies in Changle, Fuzhou this year are also working hard to add new functions to low-carbon and environmentally friendly textile materials. Continue to watch the report.

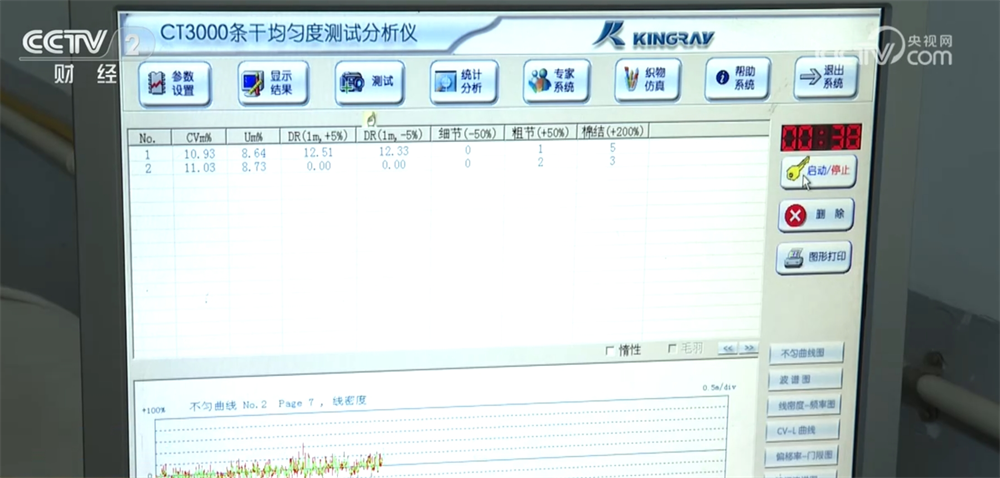

In the production workshop of a leading cotton spinning enterprise in Changle, Fuzhou, the reporter saw that as soon as construction started after the holiday, the test production line of a new plant fiber material was put into production. This new material was jointly developed by the company and the China Institute of Textile Sciences. More than 80% of the ingredients are plant extracts, and flame retardant properties are added. Small-scale production testing has been completed. After calculation, the cost will be reduced by more than one-third compared to similar products with imported costs.

Shi Songwei, chief engineer of a textile company in Fujian, said: "This material is extracted from some natural plants such as bamboo slurry and cotton slurry, and is mainly used to replace some petroleum products, such as polyester and nylon. After we started construction this time, we have made improvements in process parameters and a series of product equipment accessories, trying to enable our equipment to adapt to this new green product as soon as possible."

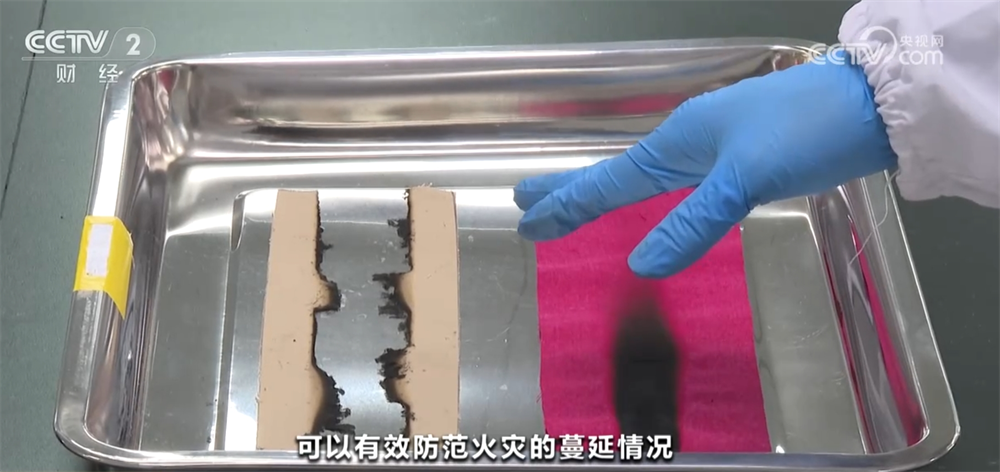

After the start of construction, the company also immediately sent the latest produced samples to test the flame retardant performance. At the Fujian Provincial Fiber Inspection Center, the reporter saw that traditional plant fiber fabrics were quickly burned through under open flames, while the new plant fiber fabrics were heated on open flames for 12 seconds but were almost not ignited.

During the visit, the reporter also saw that although this new material will further optimize the ingredients and production process, some downstream companies are already designing new products around this new material, including tooling used in the petrochemical, railway, electricity and other industries.

Huang Jinfeng, sales director of a garment company in Fuzhou, Fujian, said: "Customers have increasingly demanded green fibers. This year, nearly 30% of customers said that they can use green fibers as much as possible while meeting the needs of anti-static flame retardant multifunctional functions. It is expected that clothing with this material will be launched in the second half of the year."